Product center

Hot Products

Contact Us

Sales Department Tel:

0534-5433137 / 0534-5433136

Technical Department Tel:

18866073876 / 0534-5434137

Address: Xinghua Road, Qihe Economic Development Zone, Shandong, China

Boiling granulator

Classification:Granulating Drying Equipment

Introduction:By powder granulation, improve flowability and reduce dust flying. The dissolution properties of powders were improved by...

Technical department telephone:18866073876 / 0534-5434137

Sales Department Tel:0534-5433137 / 0534-5433136

E-mail:[email protected]

Order Hotline:400-829-7199

Can be customized according to customer requirements

Details

Product use

Granulation and coating of medicine. Granulation: tabletting granule, granule, capsule granule. Coating: granules, pills, protective layer, color release, film, enteric coated. Food granulation and coating. Stir fry sugar, coffee, cocoa powder, cream powder, juice, amino acid, seasoning, puffed food. Granulation of pesticides, pigments, pigments and dyes. Powder, granule, block, material drying.

Product features

By powder granulation, improve flowability and reduce dust flying. The dissolution properties of powders were improved by granulation. Mixing granulation drying is completed in one machine. Antistatic filter cloth is adopted, and the equipment is safe to operate. Set pressure relief hole, once the explosion, personnel are not injured. The equipment has no dead angle, and the loading and unloading materials are light, fast and easy to wash. It conforms to the "GMP" standard. High degree of automation, with program control, analog screen display technology for users to choose.

Working principle

The powdery material into hopper in the sealed container, due to thermal airflow, the powder suspended in fluid like circulation, homogeneous mixing, and the mist sprayed into the container binder wetting powder, the powder particles cemented loose grain, at the same time, due to the high heat flow drying, water constantly evaporation, continuous solidification powder, lead the process repeated, ideal for the formation of microporous, uniform spherical particles, complete mixing, a container in the three processes of granulation, drying. The water content and disintegration time of the solid preparations were used as the indexes to test the result. Results: when the solid preparations were dried, the boiling drying method was significantly different from the traditional drying method (P0.01).

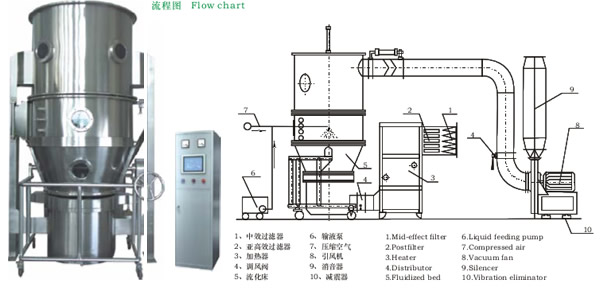

Technological process

1, Car 2, Control valve 3, Filter 4, Sub high efficiency filter 5, A heater 6, Feed pump 7, Fan 8, Silencer

Company information

Shandong Luli medicine equipment manufacturing and installation Co. Ltd. is a company engaged in the extraction, concentration and drying engineering technology development of high-tech enterprises, specializing in the extraction, concentration and drying technology and equipment research and development, design, manufacture, installation, commissioning and technical consultation!

Counseling hotline : 400-011-0271

Other products

Client messages

| Name : | * |

| Phone: | * |

| Message content: | |

Recommended news

- 2017-08-07The use of flash dryer in chemical industry

- 2017-08-07GMP requirements and extraction enrichment equipment

- 2017-08-02Six advantages of falling film evaporator

- 2017-08-01Three forms of scraper evaporator

- 2017-08-01Working principle of three effect evaporator

- 2017-08-01Matters needing attention in production of spray drier

- 2017-08-01How to achieve cyclic heating and cooling?

- 2017-08-01Maintenance knowledge and cleaning method of sanitary equipment

- 2017-08-01Preparation before extraction, concentration, inspection

- 2017-08-01Operation points of spray drying equipment

- 2017-08-01Common maintenance knowledge and cleaning method of crystallizing pot

- 2017-08-01The fresh air needed in the flash dryer is introduced by the filter

- 2017-08-01Condenser refrigeration system

- 2017-08-01What is a reaction kettle?

- 2017-08-01Overview and development process of flash drying

- 2017-08-01What is the principle of an evaporator?

- 2017-08-01Shandong pharmaceutical intermediate production company workshop equipment and piping installation project in construction

- 2017-08-01Our company is the construction of the sewage treatment system installation project of Zhangjiagang biochemical company

- 2017-08-01LPG high speed centrifugal spray dryer test machine successfully

- 2017-08-01Warmly celebrate our company won seven patents on utility models, warmly celebrate our company won seven patent certificate of utility model